-

×

Titrateur automatique TitroLine™ 5000

2 × د.ت 0,000

Titrateur automatique TitroLine™ 5000

2 × د.ت 0,000 -

×

Cassettes d'inclusion avec couvercle B/250, blanc

1 × د.ت 0,000

Cassettes d'inclusion avec couvercle B/250, blanc

1 × د.ت 0,000 -

×

Test de gradient thermique 2.0

1 × د.ت 0,000

Test de gradient thermique 2.0

1 × د.ت 0,000 -

×

Labyrinthe en T

1 × د.ت 0,000

Labyrinthe en T

1 × د.ت 0,000 -

×

Roues Instrumentées pour Exercice Spontané

1 × د.ت 0,000

Roues Instrumentées pour Exercice Spontané

1 × د.ت 0,000 -

×

Flacon ISO ambré bouchon bleu 1000 ml, GL80, SIMAX

2 × د.ت 0,000

Flacon ISO ambré bouchon bleu 1000 ml, GL80, SIMAX

2 × د.ت 0,000 -

×

Analyseur d’humidité MA37

1 × د.ت 0,000

Analyseur d’humidité MA37

1 × د.ت 0,000 -

×

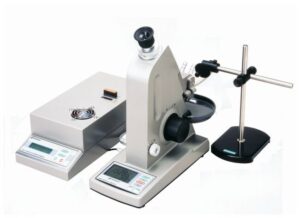

Automatic Digital Refractometer, Model: RX-7000i

1 × د.ت 0,000

Automatic Digital Refractometer, Model: RX-7000i

1 × د.ت 0,000 -

×

SI Analytics™ Titrateurs TitroLine™ série 7800

1 × د.ت 0,000

SI Analytics™ Titrateurs TitroLine™ série 7800

1 × د.ت 0,000 -

×

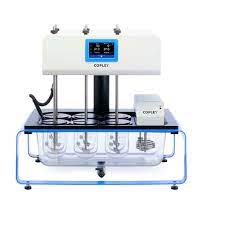

DIS 600i Test de dissolution des comprimés

1 × د.ت 0,000

DIS 600i Test de dissolution des comprimés

1 × د.ت 0,000 -

×

Broyeur Ultra Centrifuge ZM 300

1 × د.ت 0,000

Broyeur Ultra Centrifuge ZM 300

1 × د.ت 0,000 -

×

Concentrateur centrifuge réfrigéré CentriVap résistant aux acides

1 × د.ت 0,000

Concentrateur centrifuge réfrigéré CentriVap résistant aux acides

1 × د.ت 0,000 -

×

X100 40ml EPA Screw Neck Vial, 95 x 27.5mm, amber

1 × د.ت 0,000

X100 40ml EPA Screw Neck Vial, 95 x 27.5mm, amber

1 × د.ت 0,000 -

×

Velp Scientifica™ Agitateur vertical numérique DLS

2 × د.ت 0,000

Velp Scientifica™ Agitateur vertical numérique DLS

2 × د.ت 0,000 -

×

Gilson™ Pointes de filtre PIPETMAN™ Tipack™

1 × د.ت 0,000

Gilson™ Pointes de filtre PIPETMAN™ Tipack™

1 × د.ت 0,000 -

×

Kit de stress végétal (PSK)

3 × د.ت 0,000

Kit de stress végétal (PSK)

3 × د.ت 0,000 -

×

Réfractomètre du type Abbe à longueur d’onde

2 × د.ت 0,000

Réfractomètre du type Abbe à longueur d’onde

2 × د.ت 0,000 -

×

ZEISS™ Axiocam 212 color

1 × د.ت 0,000

ZEISS™ Axiocam 212 color

1 × د.ت 0,000 -

×

ZEISS LSM 900 avec Airyscan 2

1 × د.ت 0,000

ZEISS LSM 900 avec Airyscan 2

1 × د.ت 0,000 -

×

Lyophilisateurs à console FreeZone

1 × د.ت 0,000

Lyophilisateurs à console FreeZone

1 × د.ت 0,000 -

×

Simulateur ALS adulte

1 × د.ت 0,000

Simulateur ALS adulte

1 × د.ت 0,000 -

×

Photomètre 5-en-1 MD 100 : Chlore, pH, acide cyanurique, alcalinité-M, dureté du calcium

2 × د.ت 0,000

Photomètre 5-en-1 MD 100 : Chlore, pH, acide cyanurique, alcalinité-M, dureté du calcium

2 × د.ت 0,000 -

×

Processus 11 Extrudeuse parallèle à double vis

2 × د.ت 0,000

Processus 11 Extrudeuse parallèle à double vis

2 × د.ت 0,000 -

×

Spectrophotomètre NanoPhotometer C40

1 × د.ت 0,000

Spectrophotomètre NanoPhotometer C40

1 × د.ت 0,000 -

×

Flacon ISO Simax BRUN c+b bleue 5 litres

1 × د.ت 0,000

Flacon ISO Simax BRUN c+b bleue 5 litres

1 × د.ت 0,000 -

×

Concentrateur à vide d’ADN

1 × د.ت 0,000

Concentrateur à vide d’ADN

1 × د.ت 0,000 -

×

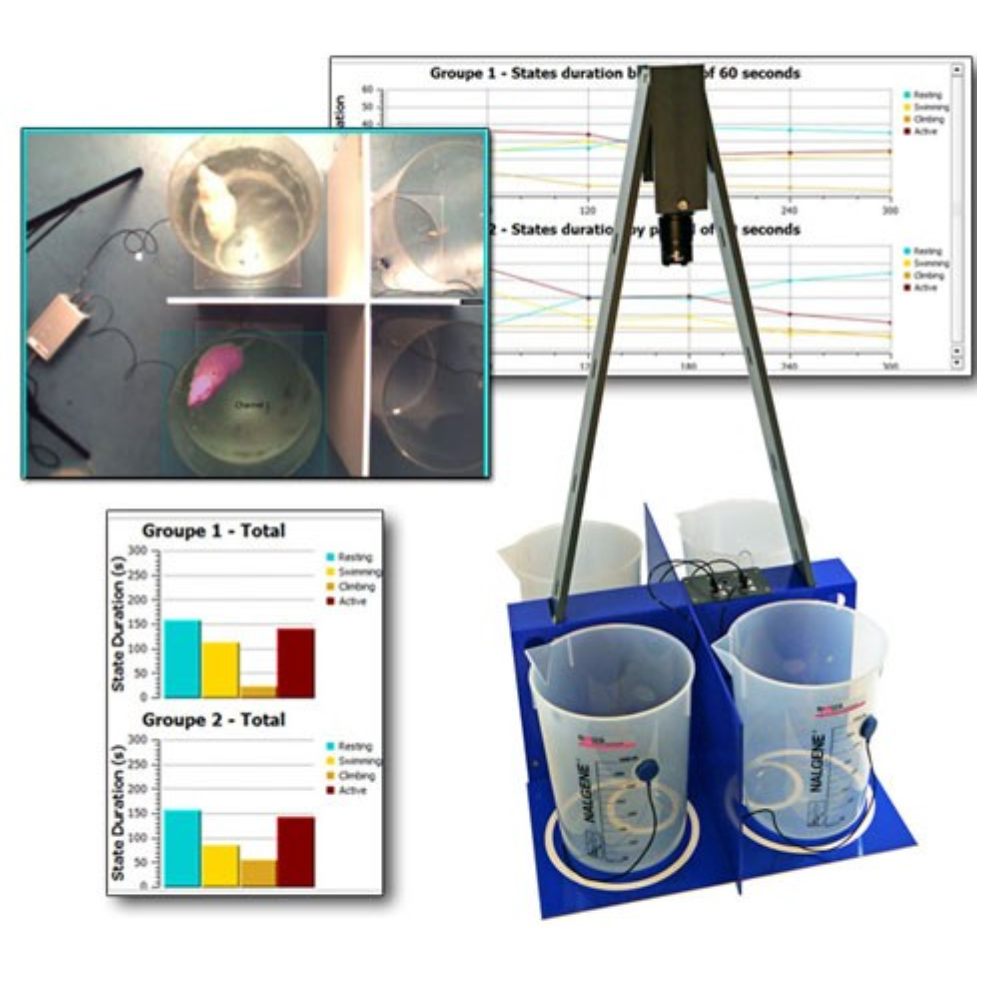

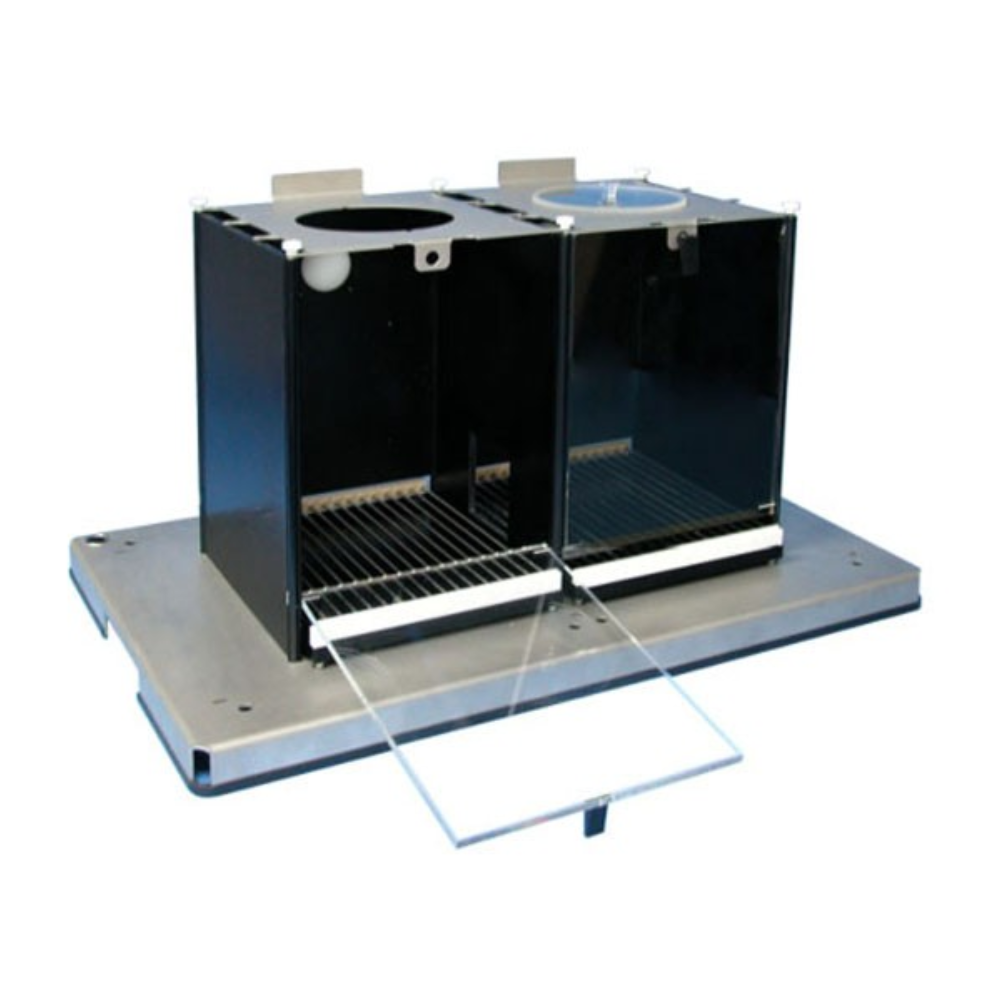

Test de Nage Forcée: Nouveau FST DUAL SENSOR

2 × د.ت 0,000

Test de Nage Forcée: Nouveau FST DUAL SENSOR

2 × د.ت 0,000 -

×

RETSCH Kit de tamis de test en acier inox, 305 x 40 mm (dia. x H), certifié ISO

1 × د.ت 0,000

RETSCH Kit de tamis de test en acier inox, 305 x 40 mm (dia. x H), certifié ISO

1 × د.ت 0,000 -

×

PISTON LISSE ELVEHJEM 2ML L'UNITE

1 × د.ت 0,000

PISTON LISSE ELVEHJEM 2ML L'UNITE

1 × د.ت 0,000 -

×

Tube à essai grad. p/centrifugeur PP,15ml (50pcs)

1 × د.ت 0,000

Tube à essai grad. p/centrifugeur PP,15ml (50pcs)

1 × د.ت 0,000 -

×

Four horizontal à tubes haute température

1 × د.ت 0,000

Four horizontal à tubes haute température

1 × د.ت 0,000 -

×

Batterie 6 chauffe-ballons Macro-KJELDAHL

1 × د.ت 0,000

Batterie 6 chauffe-ballons Macro-KJELDAHL

1 × د.ت 0,000 -

×

Duran™ Éprouvettes de mesure

2 × د.ت 0,000

Duran™ Éprouvettes de mesure

2 × د.ت 0,000 -

×

Armoire de stockage extérieur pour les bouteilles de gaz G-LINE

1 × د.ت 0,000

Armoire de stockage extérieur pour les bouteilles de gaz G-LINE

1 × د.ت 0,000 -

×

X960 Pointe Filtre Fisherbrand Sureone 30-300µl, c

1 × د.ت 0,000

X960 Pointe Filtre Fisherbrand Sureone 30-300µl, c

1 × د.ت 0,000 -

×

Test de friabilité des comprimés

2 × د.ت 0,000

Test de friabilité des comprimés

2 × د.ت 0,000 -

×

Erlab™ Hotte filtrante sans conduit Captair™ Smart 321

1 × د.ت 0,000

Erlab™ Hotte filtrante sans conduit Captair™ Smart 321

1 × د.ت 0,000 -

×

BROYEUR À COUTEAUX SM 200

2 × د.ت 0,000

BROYEUR À COUTEAUX SM 200

2 × د.ت 0,000 -

×

Armoires ventilées à filtration FX-LINE

1 × د.ت 0,000

Armoires ventilées à filtration FX-LINE

1 × د.ت 0,000 -

×

Dispositif d’adaptation Reflex FIX

2 × د.ت 0,000

Dispositif d’adaptation Reflex FIX

2 × د.ت 0,000 -

×

Memmert™ Etuve avec Double affich UN30pa

1 × د.ت 0,000

Memmert™ Etuve avec Double affich UN30pa

1 × د.ت 0,000 -

×

SI Analytics™ Titrateurs volumétriques™ 7500

1 × د.ت 0,000

SI Analytics™ Titrateurs volumétriques™ 7500

1 × د.ت 0,000 -

×

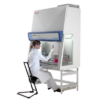

Enceintes de sécurité biologique

2 × د.ت 0,000

Enceintes de sécurité biologique

2 × د.ت 0,000 -

×

Fusion Absolute – Système d’imagerie

1 × د.ت 0,000

Fusion Absolute – Système d’imagerie

1 × د.ت 0,000 -

×

Cole-Parmer™ Incubateur à agitation Stuart™

1 × د.ت 0,000

Cole-Parmer™ Incubateur à agitation Stuart™

1 × د.ت 0,000 -

×

Évaporateur concentrateur Stuart

1 × د.ت 0,000

Évaporateur concentrateur Stuart

1 × د.ت 0,000 -

×

Asclepius TBK 65 4K Table de dissection virtuelle

1 × د.ت 0,000

Asclepius TBK 65 4K Table de dissection virtuelle

1 × د.ت 0,000 -

×

Pates et sticks diamantés

1 × د.ت 0,000

Pates et sticks diamantés

1 × د.ت 0,000 -

×

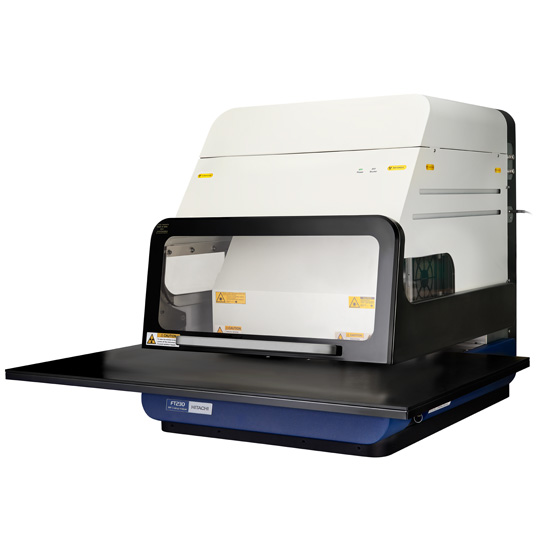

Analyseurs XRF à microspot de paillasse | Gammes FT et X-Strata | FT160

1 × د.ت 0,000

Analyseurs XRF à microspot de paillasse | Gammes FT et X-Strata | FT160

1 × د.ت 0,000 -

×

Analyseurs XRF à microspot de paillasse | Gammes FT et X-Strata | FT110A

1 × د.ت 0,000

Analyseurs XRF à microspot de paillasse | Gammes FT et X-Strata | FT110A

1 × د.ت 0,000 -

×

Oeil

1 × د.ت 0,000

Oeil

1 × د.ت 0,000 -

×

Broyeur à mortier RM 200

2 × د.ت 0,000

Broyeur à mortier RM 200

2 × د.ت 0,000 -

×

Labconco™ Système de concentration sous vide

2 × د.ت 0,000

Labconco™ Système de concentration sous vide

2 × د.ت 0,000 -

×

ZEISS™ – Lightsheet 7

1 × د.ت 0,000

ZEISS™ – Lightsheet 7

1 × د.ت 0,000 -

×

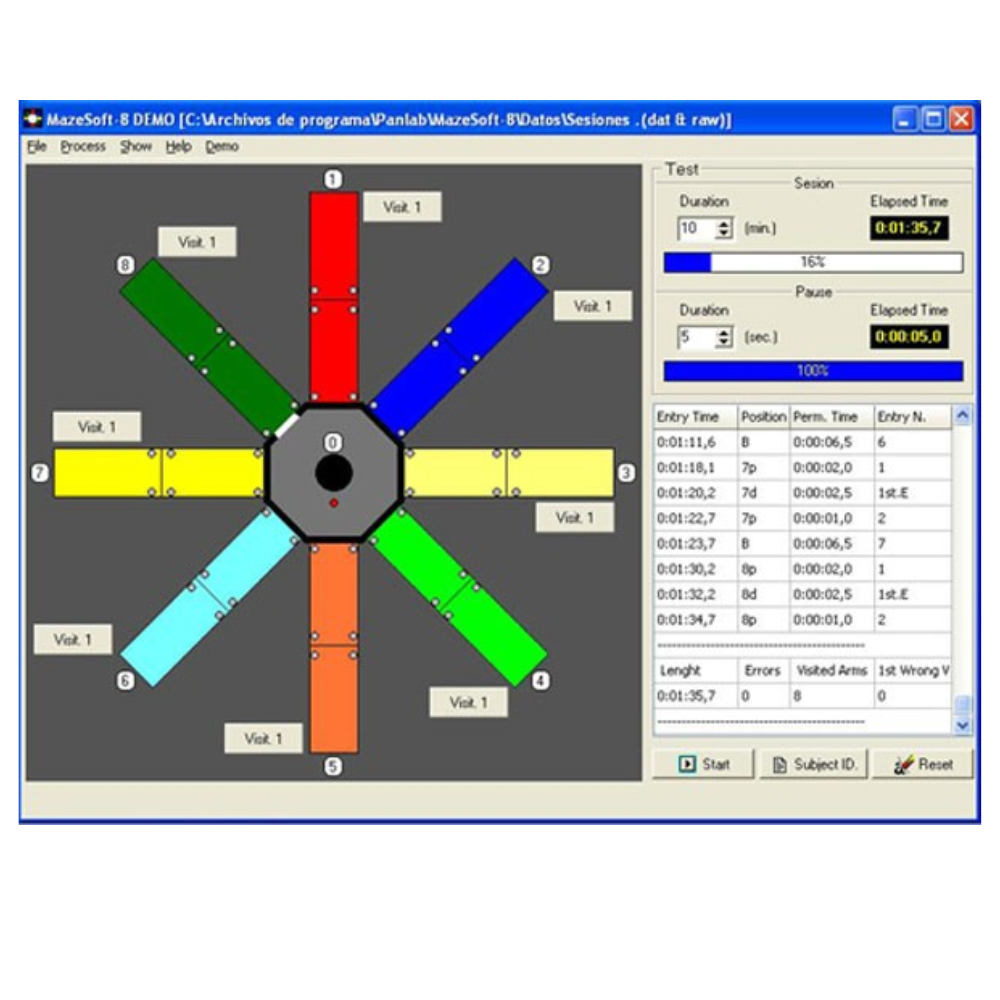

Logiciel MAZESOFT-8

1 × د.ت 0,000

Logiciel MAZESOFT-8

1 × د.ت 0,000 -

×

MD 100 Eau de chaudière 10 paramètre

1 × د.ت 0,000

MD 100 Eau de chaudière 10 paramètre

1 × د.ت 0,000 -

×

Offre géologie , préparation des lames minces

1 × د.ت 0,000

Offre géologie , préparation des lames minces

1 × د.ت 0,000 -

×

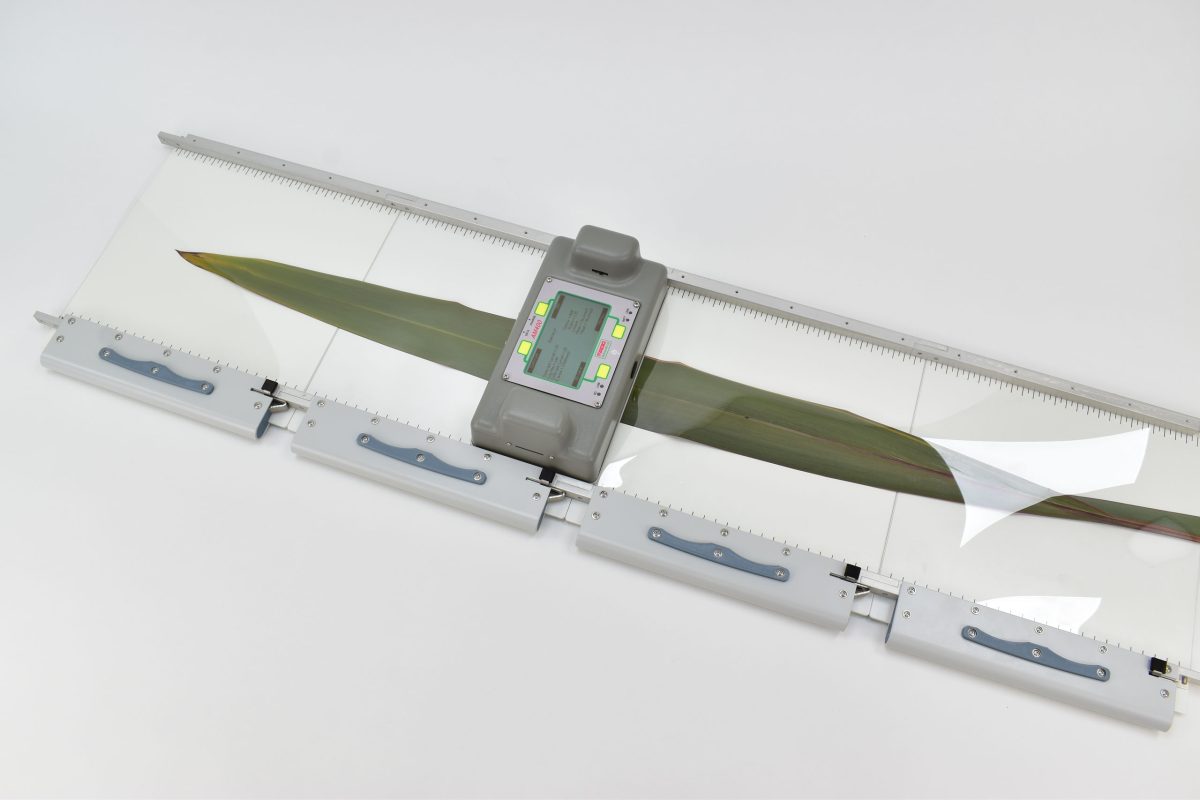

Système de photosynthèse compact LCi T

1 × د.ت 0,000

Système de photosynthèse compact LCi T

1 × د.ت 0,000 -

×

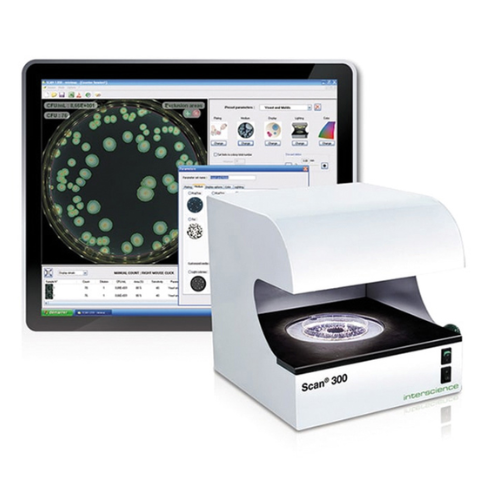

Compteur de colonies Scan 300

1 × د.ت 0,000

Compteur de colonies Scan 300

1 × د.ت 0,000 -

×

Pied pour ulcère pédieux de pression chez le sujet âgé

1 × د.ت 0,000

Pied pour ulcère pédieux de pression chez le sujet âgé

1 × د.ت 0,000 -

×

Rhéomètres HAAKE™ MARS™

1 × د.ت 0,000

Rhéomètres HAAKE™ MARS™

1 × د.ت 0,000 -

×

Photomètre à paramètre unique MD 100 : Chlore DUO

1 × د.ت 0,000

Photomètre à paramètre unique MD 100 : Chlore DUO

1 × د.ت 0,000 -

×

Duran™ Tubes à essai en verre à rebord droit

1 × د.ت 0,000

Duran™ Tubes à essai en verre à rebord droit

1 × د.ت 0,000 -

×

Flacon ISO Simax cap+bague bleu 2000ml

1 × د.ت 0,000

Flacon ISO Simax cap+bague bleu 2000ml

1 × د.ت 0,000 -

×

Shuttle Boxes

1 × د.ت 0,000

Shuttle Boxes

1 × د.ت 0,000 -

×

Unités de filtration PES intégrée

1 × د.ت 0,000

Unités de filtration PES intégrée

1 × د.ت 0,000 -

×

Kit de photomètre MD100 2-en-1

1 × د.ت 0,000

Kit de photomètre MD100 2-en-1

1 × د.ت 0,000 -

×

Stirrer shaft PTFE 12x750EX mm

1 × د.ت 0,000

Stirrer shaft PTFE 12x750EX mm

1 × د.ت 0,000 -

×

Le Cube

1 × د.ت 0,000

Le Cube

1 × د.ت 0,000 -

×

SI Analytics™ Titrateur de module TitroLine

1 × د.ت 0,000

SI Analytics™ Titrateur de module TitroLine

1 × د.ت 0,000 -

×

DURAN™ Bocal, avec couvercle à bouton, à bord poli

1 × د.ت 0,000

DURAN™ Bocal, avec couvercle à bouton, à bord poli

1 × د.ت 0,000 -

×

Flacon ISO bouchon bleu 50 ml, GL32, SIMAX

2 × د.ت 0,000

Flacon ISO bouchon bleu 50 ml, GL32, SIMAX

2 × د.ت 0,000 -

×

Varian Prostar 340 345 Deuterium Lamp

1 × د.ت 0,000

Varian Prostar 340 345 Deuterium Lamp

1 × د.ت 0,000 -

×

Compteur de surface de feuille portable AM400

2 × د.ت 0,000

Compteur de surface de feuille portable AM400

2 × د.ت 0,000 -

×

Spectrophotomètre UV/Visible série 72

1 × د.ت 0,000

Spectrophotomètre UV/Visible série 72

1 × د.ت 0,000 -

×

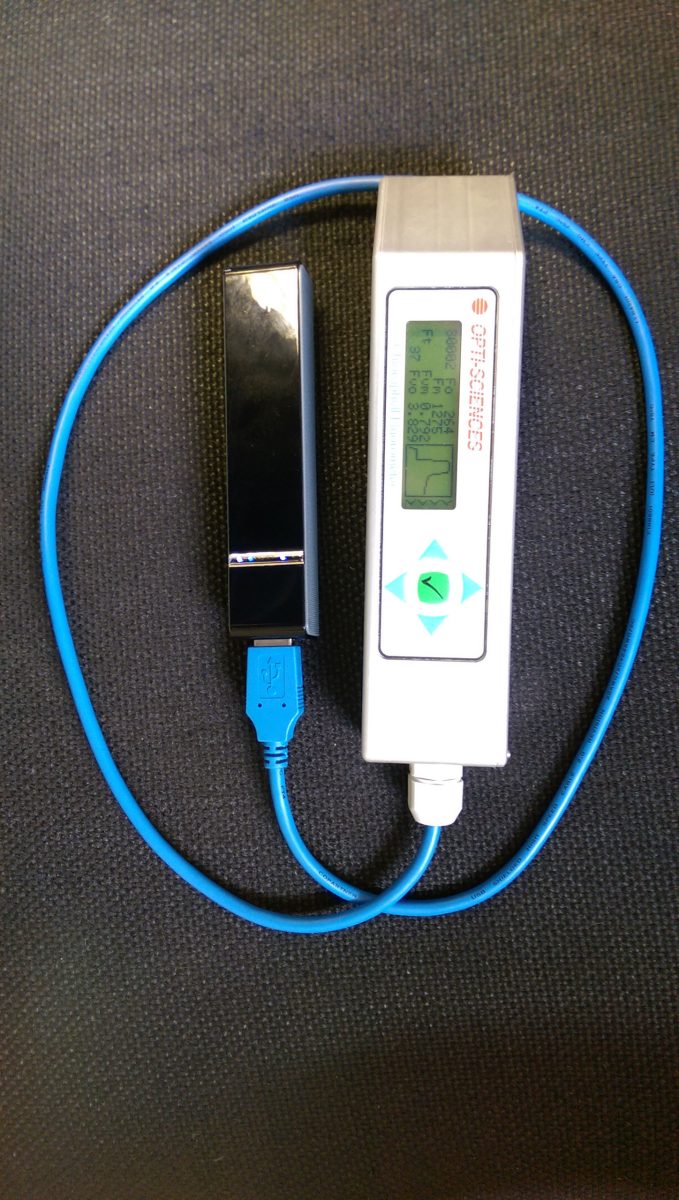

Compteur multi-pigments MPM-100

1 × د.ت 0,000

Compteur multi-pigments MPM-100

1 × د.ت 0,000 -

×

Labconco™ Évaporateurs à sec RapidVap

1 × د.ت 0,000

Labconco™ Évaporateurs à sec RapidVap

1 × د.ت 0,000 -

×

Moniteur de patient simulé avec analyse et rétroaction sur la RCP - REALITi 360 Pro

1 × د.ت 0,000

Moniteur de patient simulé avec analyse et rétroaction sur la RCP - REALITi 360 Pro

1 × د.ت 0,000 -

×

DUROMETRE Semi-Automatique HZ2-2

1 × د.ت 0,000

DUROMETRE Semi-Automatique HZ2-2

1 × د.ت 0,000 -

×

X24 Fisherbrand 120ml WM clear glass type 3 bottle

1 × د.ت 0,000

X24 Fisherbrand 120ml WM clear glass type 3 bottle

1 × د.ت 0,000 -

×

Four à allumage rapide

1 × د.ت 0,000

Four à allumage rapide

1 × د.ت 0,000 -

×

Implen™ OD600 DiluPhotometer

1 × د.ت 0,000

Implen™ OD600 DiluPhotometer

1 × د.ت 0,000 -

×

Chambre climatique Conditions Constantes

1 × د.ت 0,000

Chambre climatique Conditions Constantes

1 × د.ت 0,000 -

×

Photomètre 3-en-1 MD 100 : Chlore, pH, alcalinité-M

1 × د.ت 0,000

Photomètre 3-en-1 MD 100 : Chlore, pH, alcalinité-M

1 × د.ت 0,000 -

×

Poste de Sécurité Microbiologique PSM- Bioban

1 × د.ت 0,000

Poste de Sécurité Microbiologique PSM- Bioban

1 × د.ت 0,000 -

×

Suspensions d'allumine

1 × د.ت 0,000

Suspensions d'allumine

1 × د.ت 0,000 -

×

Flacon ISO bouchon bleu 50 ml, GL32, SIMAX

1 × د.ت 0,000

Flacon ISO bouchon bleu 50 ml, GL32, SIMAX

1 × د.ت 0,000 -

×

ZEISS™Axiocam 305 colo

1 × د.ت 0,000

ZEISS™Axiocam 305 colo

1 × د.ت 0,000 -

×

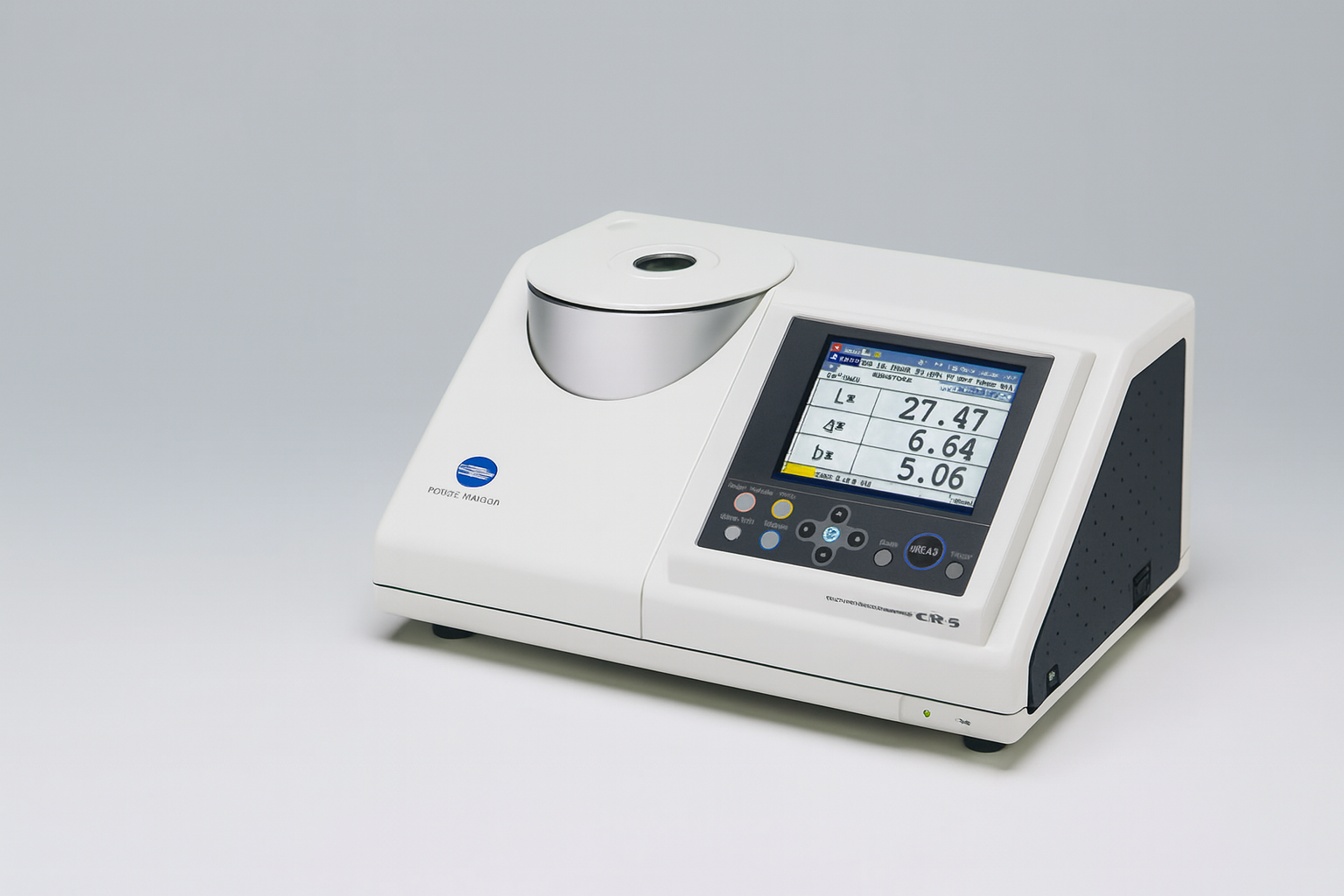

COLORIMETRE FILTRES 440/680NM RECH

1 × د.ت 0,000

COLORIMETRE FILTRES 440/680NM RECH

1 × د.ت 0,000 -

×

Memmert™ Incubateur à CO2 ICO

1 × د.ت 0,000

Memmert™ Incubateur à CO2 ICO

1 × د.ت 0,000 -

×

ZEISS™ – Loupe Stemi 305

1 × د.ت 0,000

ZEISS™ – Loupe Stemi 305

1 × د.ت 0,000 -

×

Arène Open Field

1 × د.ت 0,000

Arène Open Field

1 × د.ت 0,000 -

×

X300 Tube soda 8x35x0,65mm sans rebord Durham Fish

1 × د.ت 0,000

X300 Tube soda 8x35x0,65mm sans rebord Durham Fish

1 × د.ت 0,000 -

×

NanoPhotomètre® NP80

1 × د.ت 0,000

NanoPhotomètre® NP80

1 × د.ت 0,000 -

×

Velp Scientifica™ Agitateur vertical numérique HDL

1 × د.ت 0,000

Velp Scientifica™ Agitateur vertical numérique HDL

1 × د.ت 0,000 -

×

Concentrateur complet CentriVap™

1 × د.ت 0,000

Concentrateur complet CentriVap™

1 × د.ت 0,000 -

×

Analyseurs LIBS portables | Gamme Vulcan+

1 × د.ت 0,000

Analyseurs LIBS portables | Gamme Vulcan+

1 × د.ت 0,000 -

×

DUROMETRE Automatique HZ2-4

1 × د.ت 0,000

DUROMETRE Automatique HZ2-4

1 × د.ت 0,000 -

×

Flacon ISO Simax cap+bague bleu 500ml

1 × د.ت 0,000

Flacon ISO Simax cap+bague bleu 500ml

1 × د.ت 0,000 -

×

Interscience™ Compteur de colonies Scan 100

1 × د.ت 0,000

Interscience™ Compteur de colonies Scan 100

1 × د.ت 0,000 -

×

Jauges portatives d'épaisseur de revêtement

1 × د.ت 0,000

Jauges portatives d'épaisseur de revêtement

1 × د.ت 0,000

Sous-total : د.ت 0,000