-

×

RO Membranes for small RiOs& Elix

1 × د.ت 0,000

RO Membranes for small RiOs& Elix

1 × د.ت 0,000 -

×

X40 30ml flacon verre blanc fermé avec bouchon a v

1 × د.ت 0,000

X40 30ml flacon verre blanc fermé avec bouchon a v

1 × د.ت 0,000 -

×

TraceableGO Blue-Tooth Temp/Humidity

1 × د.ت 0,000

TraceableGO Blue-Tooth Temp/Humidity

1 × د.ت 0,000 -

×

Poids etalon cylindrique 5g F2 inox

1 × د.ت 0,000

Poids etalon cylindrique 5g F2 inox

1 × د.ت 0,000 -

×

X12 Flacon Fisherbrand,60ml,HDPE,Transp.,Col Large

1 × د.ت 0,000

X12 Flacon Fisherbrand,60ml,HDPE,Transp.,Col Large

1 × د.ت 0,000 -

×

BUCHNER PORCELAINE FILTRE 90MM

1 × د.ت 0,000

BUCHNER PORCELAINE FILTRE 90MM

1 × د.ت 0,000 -

×

Corning™ Pointes de pipette, adaptation universelle : Rack stérile empilé

1 × د.ت 0,000

Corning™ Pointes de pipette, adaptation universelle : Rack stérile empilé

1 × د.ت 0,000 -

×

PROVRÖR UTAN LOCK 13X100MMFP=1000

1 × د.ت 0,000

PROVRÖR UTAN LOCK 13X100MMFP=1000

1 × د.ت 0,000 -

×

X100 BECHER TRICORNE PP 100ML GRAD

1 × د.ت 0,000

X100 BECHER TRICORNE PP 100ML GRAD

1 × د.ت 0,000 -

×

IKA Viscosimètre Rotavisc me-vi Complete

1 × د.ت 0,000

IKA Viscosimètre Rotavisc me-vi Complete

1 × د.ت 0,000 -

×

PISTON STRIE ELVEHJEM 50ML L'UNITE

1 × د.ت 0,000

PISTON STRIE ELVEHJEM 50ML L'UNITE

1 × د.ت 0,000 -

×

Aperçu: GAP-LINE - Postes de travails à flux laminaire destinés aux matières dangereuses

1 × د.ت 0,000

Aperçu: GAP-LINE - Postes de travails à flux laminaire destinés aux matières dangereuses

1 × د.ت 0,000 -

×

BUCHNER PORCELAINE FILTRE 320MM

1 × د.ت 0,000

BUCHNER PORCELAINE FILTRE 320MM

1 × د.ت 0,000 -

×

x180 Fisherbrand 500ml WM natural HDPE bottle, PE

1 × د.ت 0,000

x180 Fisherbrand 500ml WM natural HDPE bottle, PE

1 × د.ت 0,000 -

×

Four universel à convection naturelle UN55 avec SingleDISPLAY

1 × د.ت 0,000

Four universel à convection naturelle UN55 avec SingleDISPLAY

1 × د.ت 0,000 -

×

X72 Flacon Fisherbrand,60ml,HDPE,Ambré,Col Large

1 × د.ت 0,000

X72 Flacon Fisherbrand,60ml,HDPE,Ambré,Col Large

1 × د.ت 0,000 -

×

Bâton d’avivage pour disque diamanté

1 × د.ت 0,000

Bâton d’avivage pour disque diamanté

1 × د.ت 0,000 -

×

SUPPORT DIA 94MM 4 TUBES 29MM

1 × د.ت 0,000

SUPPORT DIA 94MM 4 TUBES 29MM

1 × د.ت 0,000 -

×

ZEISS™ – Scanner Axioscan 7

1 × د.ت 0,000

ZEISS™ – Scanner Axioscan 7

1 × د.ت 0,000 -

×

Asecos™ Unité d’évacuation de l’air

1 × د.ت 0,000

Asecos™ Unité d’évacuation de l’air

1 × د.ت 0,000 -

×

X2 éprouvette col rodé,verre borosilicaté,50mL gra

1 × د.ت 0,000

X2 éprouvette col rodé,verre borosilicaté,50mL gra

1 × د.ت 0,000 -

×

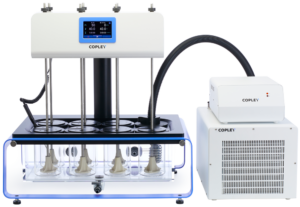

TRG 800i - Testeur de détergent - Tergotomètre

1 × د.ت 0,000

TRG 800i - Testeur de détergent - Tergotomètre

1 × د.ت 0,000 -

×

Armoires de sécurité V-LINE

1 × د.ت 0,000

Armoires de sécurité V-LINE

1 × د.ت 0,000 -

×

TRAY RADIATION HAZARD EASY CLEAN 113

1 × د.ت 0,000

TRAY RADIATION HAZARD EASY CLEAN 113

1 × د.ت 0,000 -

×

3. detergent dosing pump

1 × د.ت 0,000

3. detergent dosing pump

1 × د.ت 0,000 -

×

25 x Eco-smartFunnel Card Funnels Disposable

1 × د.ت 0,000

25 x Eco-smartFunnel Card Funnels Disposable

1 × د.ت 0,000 -

×

Poids etalon cylindrique 50g F1 inox

1 × د.ت 0,000

Poids etalon cylindrique 50g F1 inox

1 × د.ت 0,000 -

×

X960 Recharge Pointe Filtre Fisherbrand Sureone 20

1 × د.ت 0,000

X960 Recharge Pointe Filtre Fisherbrand Sureone 20

1 × د.ت 0,000 -

×

X12 Fisherbrand 500ml NM amber safety coated Packe

1 × د.ت 0,000

X12 Fisherbrand 500ml NM amber safety coated Packe

1 × د.ت 0,000 -

×

Système de photosynthèse portable avancé LCpro T

1 × د.ت 0,000

Système de photosynthèse portable avancé LCpro T

1 × د.ت 0,000 -

×

THERMOMETRE POCHE -50/300°C

1 × د.ت 0,000

THERMOMETRE POCHE -50/300°C

1 × د.ت 0,000 -

×

Système de production d’eau ultra-pure Accu100

1 × د.ت 0,000

Système de production d’eau ultra-pure Accu100

1 × د.ت 0,000 -

×

OMRÖRARSKAFT PROPELLER PTFE 16X1000X100MM

1 × د.ت 0,000

OMRÖRARSKAFT PROPELLER PTFE 16X1000X100MM

1 × د.ت 0,000 -

×

X1632 Pointe Fisherbrand SureOne 1-200µl XL (90,9m

1 × د.ت 0,000

X1632 Pointe Fisherbrand SureOne 1-200µl XL (90,9m

1 × د.ت 0,000 -

×

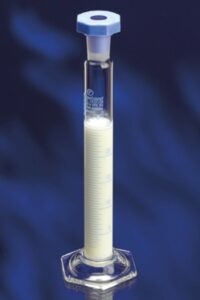

Colonnes

1 × د.ت 0,000

Colonnes

1 × د.ت 0,000 -

×

X6 Fisherbrand 1920ml WM clear glass type3 bottle,

1 × د.ت 0,000

X6 Fisherbrand 1920ml WM clear glass type3 bottle,

1 × د.ت 0,000 -

×

Rhéomètre de couple modulaire HAAKE™ PolyLab™ OS Mélangeur et Extrudeuse

1 × د.ت 0,000

Rhéomètre de couple modulaire HAAKE™ PolyLab™ OS Mélangeur et Extrudeuse

1 × د.ت 0,000 -

×

X4 Safety-Labeled 4-C Bleach Wide-Mouth Wash Bottl

1 × د.ت 0,000

X4 Safety-Labeled 4-C Bleach Wide-Mouth Wash Bottl

1 × د.ت 0,000 -

×

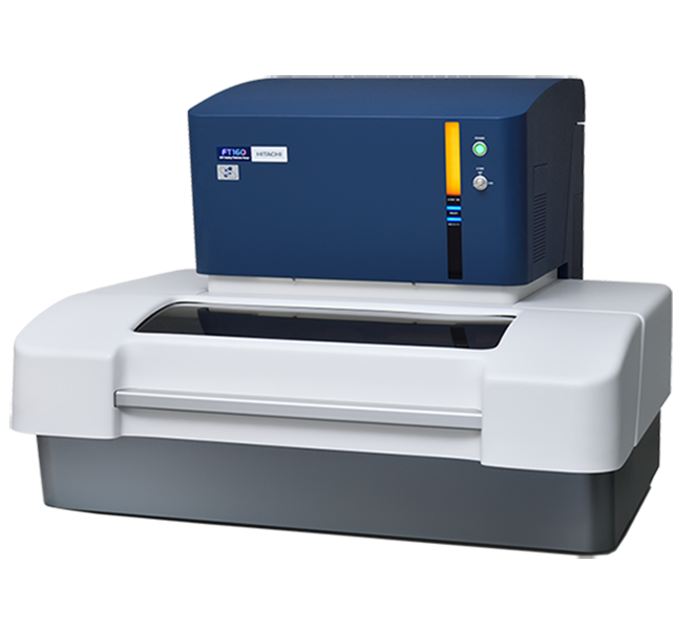

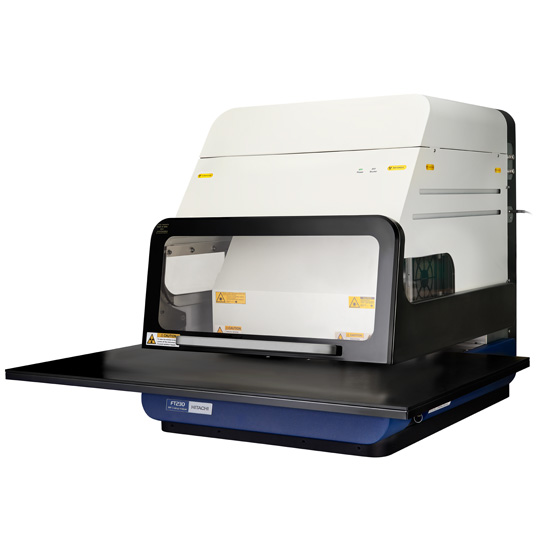

Série FT200 | XRF automatisé pour l'analyse rapide des revêtements

1 × د.ت 0,000

Série FT200 | XRF automatisé pour l'analyse rapide des revêtements

1 × د.ت 0,000

Sous-total : د.ت 0,000