-

×

Gilson™ Accessoire pour le système de pipetage complet PIPETMAN™ - Support de pipettes rotatif Carrousel™

1 × د.ت 0,000

Gilson™ Accessoire pour le système de pipetage complet PIPETMAN™ - Support de pipettes rotatif Carrousel™

1 × د.ت 0,000 -

×

X960 Recharge Pointe Filtre Fisherbrand Sureone 20

1 × د.ت 0,000

X960 Recharge Pointe Filtre Fisherbrand Sureone 20

1 × د.ت 0,000 -

×

500 x Conical Centrifuge Tube 50ml Black

2 × د.ت 0,000

500 x Conical Centrifuge Tube 50ml Black

2 × د.ت 0,000 -

×

Chauffe Ballons Série 655. 2000 ml.

1 × د.ت 0,000

Chauffe Ballons Série 655. 2000 ml.

1 × د.ت 0,000 -

×

CENTRIFUGRÖR PP SNÄPPLOCK 1,5ML RÖD FP=1000

1 × د.ت 0,000

CENTRIFUGRÖR PP SNÄPPLOCK 1,5ML RÖD FP=1000

1 × د.ت 0,000 -

×

Aperçu: GAP-LINE - Postes de travails à flux laminaire destinés aux matières dangereuses

1 × د.ت 0,000

Aperçu: GAP-LINE - Postes de travails à flux laminaire destinés aux matières dangereuses

1 × د.ت 0,000 -

×

Mélangeur de laboratoire BagMixer

1 × د.ت 0,000

Mélangeur de laboratoire BagMixer

1 × د.ت 0,000 -

×

Corning™ Pointes de pipettes sur rack à charnière taille standard, non stériles

1 × د.ت 0,000

Corning™ Pointes de pipettes sur rack à charnière taille standard, non stériles

1 × د.ت 0,000 -

×

Logiciel Bioseb CIS

1 × د.ت 0,000

Logiciel Bioseb CIS

1 × د.ت 0,000 -

×

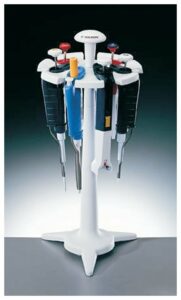

support de chargement pour pipettes

2 × د.ت 0,000

support de chargement pour pipettes

2 × د.ت 0,000 -

×

Mesh basket, Mask 8x8x1 mm, (WxDxH) 130x130x130mm

1 × د.ت 0,000

Mesh basket, Mask 8x8x1 mm, (WxDxH) 130x130x130mm

1 × د.ت 0,000 -

×

OMRÖRARGUIDE A24/40 KON UNIVERSELL PTFE vit 10MM

1 × د.ت 0,000

OMRÖRARGUIDE A24/40 KON UNIVERSELL PTFE vit 10MM

1 × د.ت 0,000 -

×

SI Analytics™ Titrateurs volumétriques™ 7500

1 × د.ت 0,000

SI Analytics™ Titrateurs volumétriques™ 7500

1 × د.ت 0,000 -

×

TRAY RADIATION HAZARD EASY CLEAN 70 X

1 × د.ت 0,000

TRAY RADIATION HAZARD EASY CLEAN 70 X

1 × د.ت 0,000 -

×

Centrifugeuse de paillasse non réfrigérée Sigma 4-5L

1 × د.ت 0,000

Centrifugeuse de paillasse non réfrigérée Sigma 4-5L

1 × د.ت 0,000 -

×

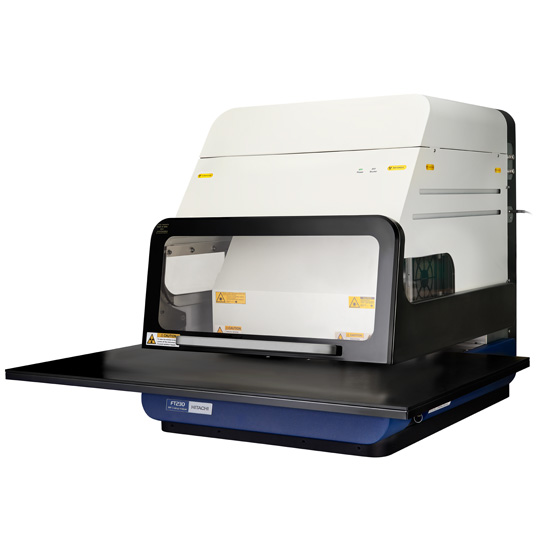

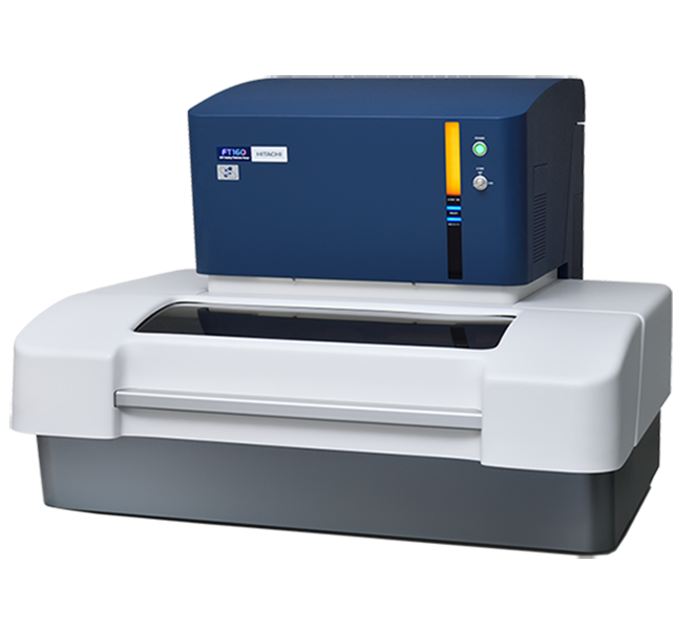

Analyseurs XRF à microspot de paillasse | Gammes FT et X-Strata | FT110A

1 × د.ت 0,000

Analyseurs XRF à microspot de paillasse | Gammes FT et X-Strata | FT110A

1 × د.ت 0,000

Sous-total : د.ت 0,000