-

×

PROVRÖR UTAN LOCK 13X100MMFP=1000

1 × د.ت 0,000

PROVRÖR UTAN LOCK 13X100MMFP=1000

1 × د.ت 0,000 -

×

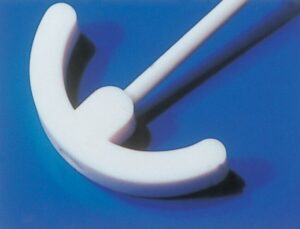

Ankerrührer, PTFE, 16 x 750EX x 180mm, Rotor 180mm

1 × د.ت 0,000

Ankerrührer, PTFE, 16 x 750EX x 180mm, Rotor 180mm

1 × د.ت 0,000 -

×

SI Analytics™ Titrateur de module TitroLine

1 × د.ت 0,000

SI Analytics™ Titrateur de module TitroLine

1 × د.ت 0,000 -

×

Microcentrifugeuse réfrigérée Sigma™1-16K

1 × د.ت 0,000

Microcentrifugeuse réfrigérée Sigma™1-16K

1 × د.ت 0,000 -

×

Spinbar magnetic stir bar

1 × د.ت 0,000

Spinbar magnetic stir bar

1 × د.ت 0,000 -

×

X250 Pointe Fisherbrand SureOne 1-5ml, cristal, no

1 × د.ت 0,000

X250 Pointe Fisherbrand SureOne 1-5ml, cristal, no

1 × د.ت 0,000 -

×

X25 Plaque PCR Fisherbrand 96 puits, jupée, PP rou

1 × د.ت 0,000

X25 Plaque PCR Fisherbrand 96 puits, jupée, PP rou

1 × د.ت 0,000 -

×

Système Kjeldahl Complet – Workstation Exklusiv

1 × د.ت 0,000

Système Kjeldahl Complet – Workstation Exklusiv

1 × د.ت 0,000 -

×

MANOMETRE +/-6895 MBAR

1 × د.ت 0,000

MANOMETRE +/-6895 MBAR

1 × د.ت 0,000 -

×

ZEISS™ -Loupe Discovery.V12

1 × د.ت 0,000

ZEISS™ -Loupe Discovery.V12

1 × د.ت 0,000 -

×

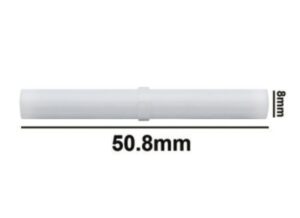

X5_TRACE_PTFE stirrer bar, pivot ring, fully trace

1 × د.ت 0,000

X5_TRACE_PTFE stirrer bar, pivot ring, fully trace

1 × د.ت 0,000 -

×

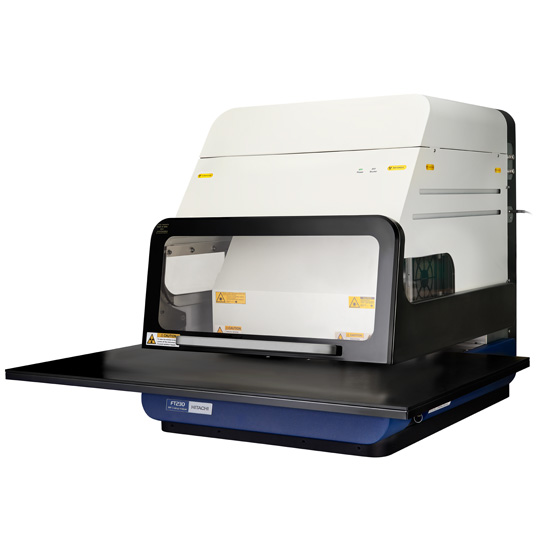

Analyseurs XRF à microspot de paillasse | Gammes FT et X-Strata | X-Strata920

1 × د.ت 0,000

Analyseurs XRF à microspot de paillasse | Gammes FT et X-Strata | X-Strata920

1 × د.ت 0,000 -

×

X20 300ml flacon verre blanc fermé avec bouchon a

1 × د.ت 0,000

X20 300ml flacon verre blanc fermé avec bouchon a

1 × د.ت 0,000 -

×

Interscience™ Compteur de colonies Scan 100

1 × د.ت 0,000

Interscience™ Compteur de colonies Scan 100

1 × د.ت 0,000 -

×

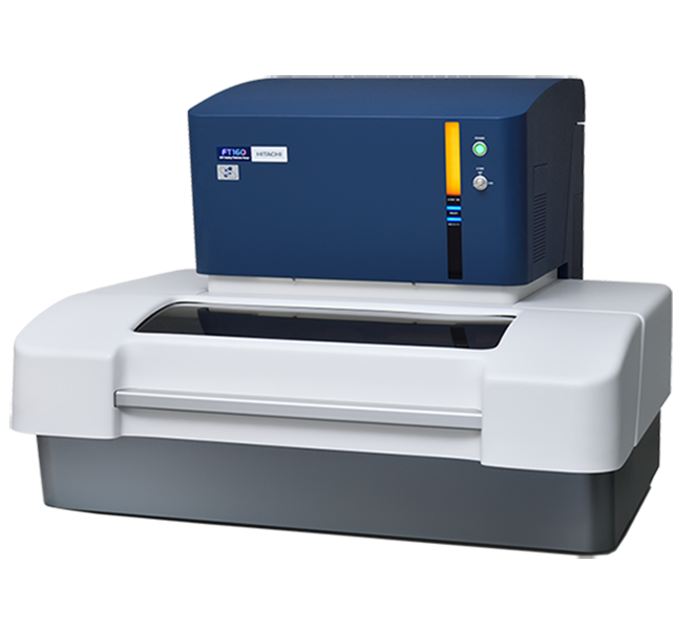

Analyseurs XRF portables | Gamme X-MET8000 Expert

1 × د.ت 0,000

Analyseurs XRF portables | Gamme X-MET8000 Expert

1 × د.ت 0,000

Sous-total : د.ت 0,000