-

×

Rhéomètres HAAKE™ MARS™

1 × د.ت 0,000

Rhéomètres HAAKE™ MARS™

1 × د.ت 0,000 -

×

Laparo Apex VR

1 × د.ت 0,000

Laparo Apex VR

1 × د.ت 0,000 -

×

Memmert™ Incubateur à CO2 ICO

1 × د.ت 0,000

Memmert™ Incubateur à CO2 ICO

1 × د.ت 0,000 -

×

Flacon ISO Simax cap+bague bleu 500ml

2 × د.ت 0,000

Flacon ISO Simax cap+bague bleu 500ml

2 × د.ت 0,000 -

×

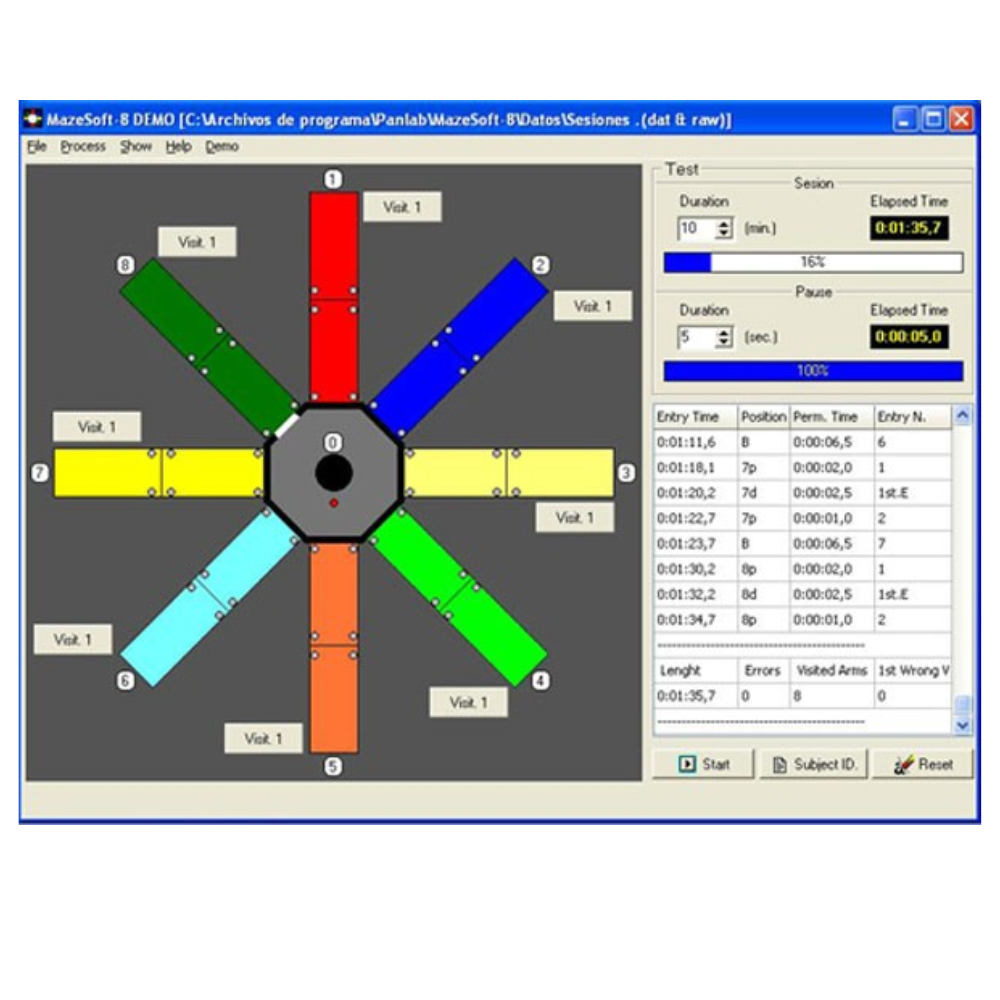

Logiciel MAZESOFT-8

1 × د.ت 0,000

Logiciel MAZESOFT-8

1 × د.ت 0,000 -

×

Offre géologie , préparation des lames minces

1 × د.ت 0,000

Offre géologie , préparation des lames minces

1 × د.ت 0,000 -

×

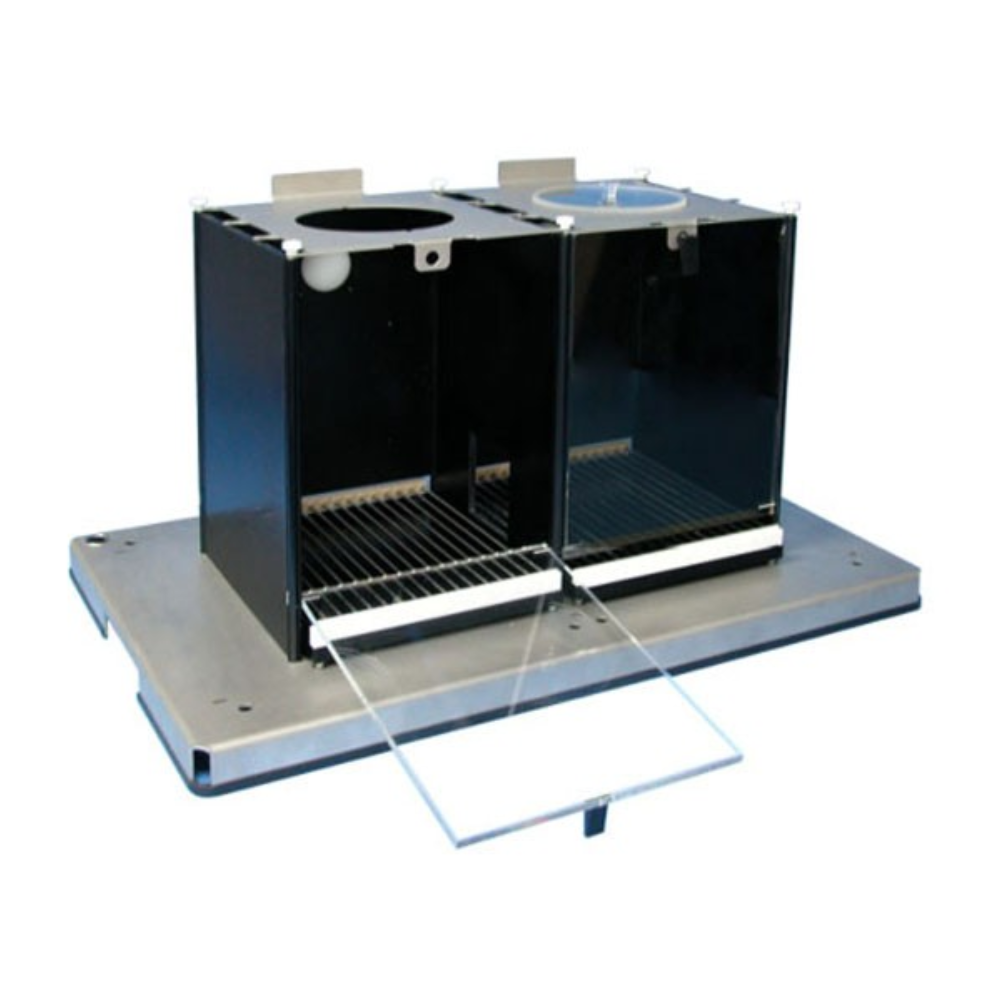

Open Field automatisé 3D pour rats et souris

1 × د.ت 0,000

Open Field automatisé 3D pour rats et souris

1 × د.ت 0,000 -

×

Aperçu: GAP-LINE - Postes de travails à flux laminaire destinés aux matières dangereuses

1 × د.ت 0,000

Aperçu: GAP-LINE - Postes de travails à flux laminaire destinés aux matières dangereuses

1 × د.ت 0,000 -

×

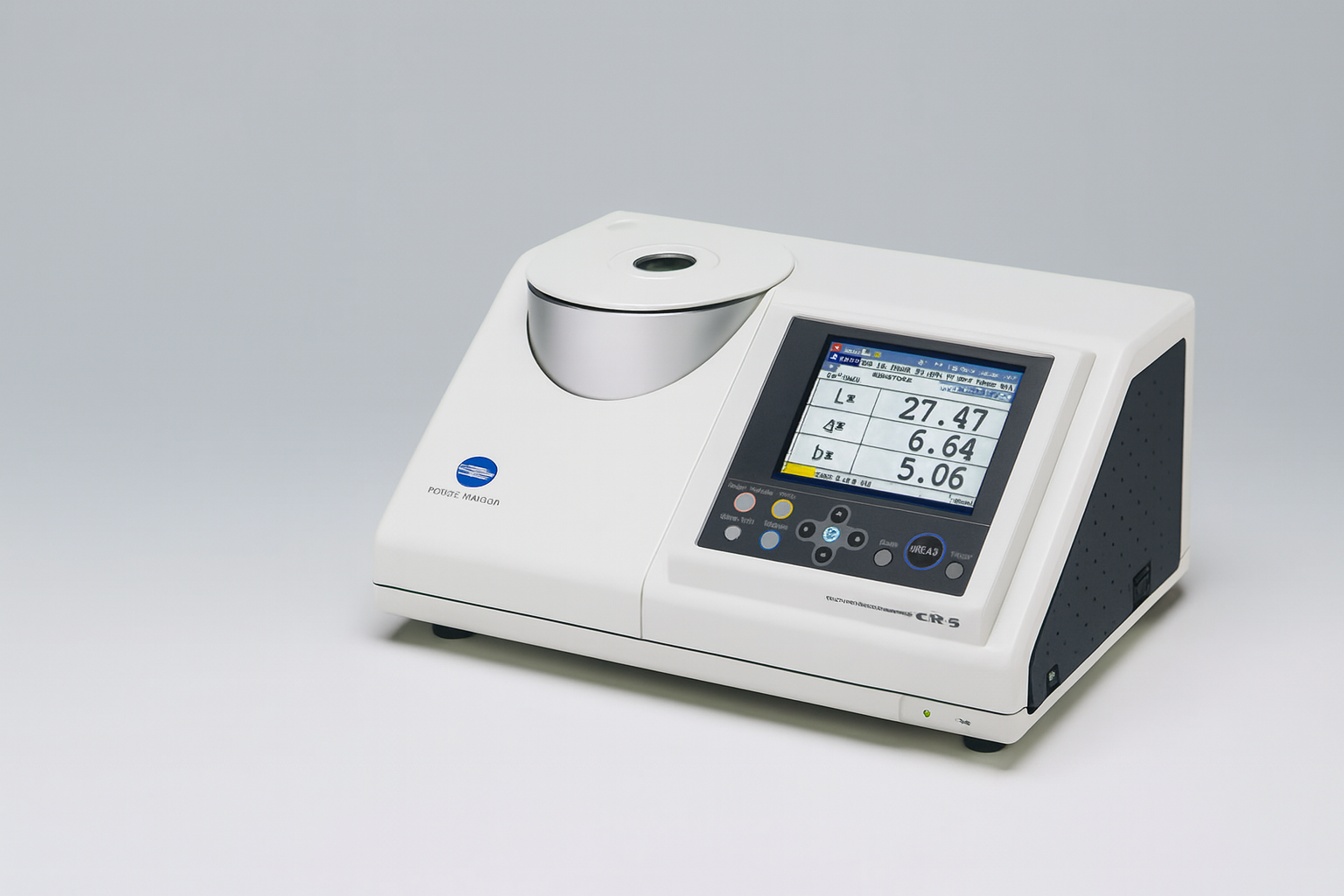

MICROTECH MX3

1 × د.ت 0,000

MICROTECH MX3

1 × د.ت 0,000 -

×

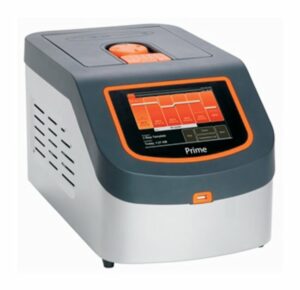

Techne Thermocycleur à gradient 5PrimeG

1 × د.ت 0,000

Techne Thermocycleur à gradient 5PrimeG

1 × د.ت 0,000 -

×

Analyseur du potentiel Stabino Zeta

2 × د.ت 0,000

Analyseur du potentiel Stabino Zeta

2 × د.ت 0,000 -

×

Système de photosynthèse compact LCi T

1 × د.ت 0,000

Système de photosynthèse compact LCi T

1 × د.ت 0,000 -

×

Shuttle Boxes

1 × د.ت 0,000

Shuttle Boxes

1 × د.ت 0,000 -

×

Flacon ISO Simax cap+bague bleu 5000ml

1 × د.ت 0,000

Flacon ISO Simax cap+bague bleu 5000ml

1 × د.ت 0,000 -

×

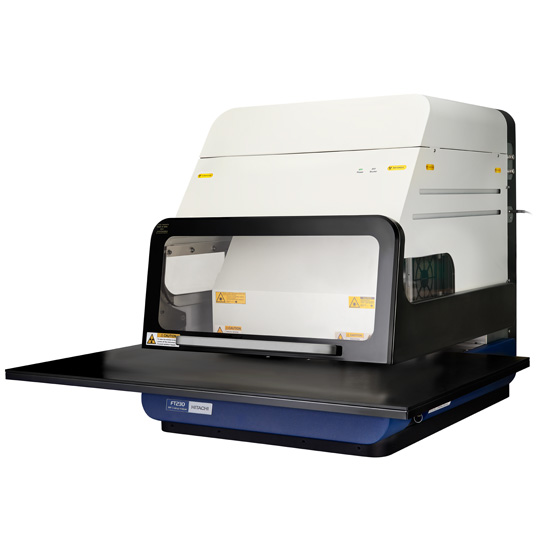

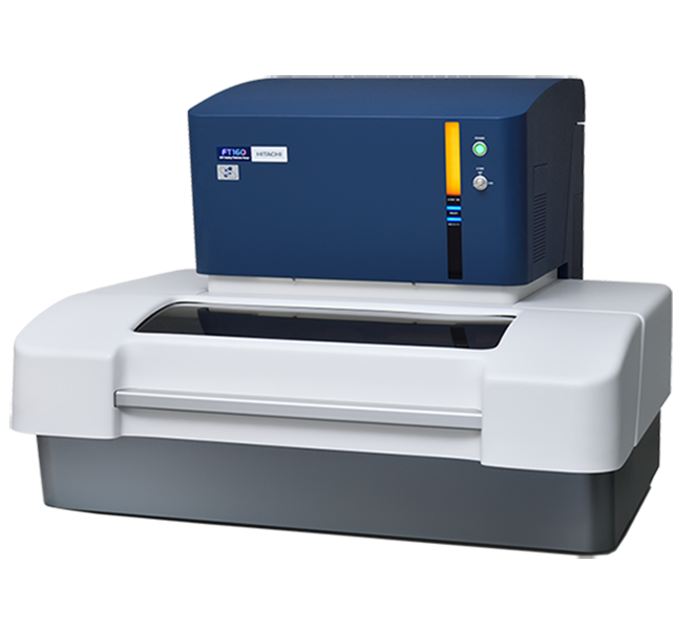

Analyseurs XRF à microspot de paillasse | Gammes FT et X-Strata | FT160

2 × د.ت 0,000

Analyseurs XRF à microspot de paillasse | Gammes FT et X-Strata | FT160

2 × د.ت 0,000 -

×

Flacon ISO bouchon bleu 50 ml, GL32, SIMAX

1 × د.ت 0,000

Flacon ISO bouchon bleu 50 ml, GL32, SIMAX

1 × د.ت 0,000 -

×

Armoire acides/bases SL-CLASSIC Avec Coffret

1 × د.ت 0,000

Armoire acides/bases SL-CLASSIC Avec Coffret

1 × د.ت 0,000 -

×

DURAN™ Tube de culture, bord droit, pour capuchon de Kapsenberg

1 × د.ت 0,000

DURAN™ Tube de culture, bord droit, pour capuchon de Kapsenberg

1 × د.ت 0,000 -

×

Logiciel Bioseb CIS

1 × د.ت 0,000

Logiciel Bioseb CIS

1 × د.ت 0,000 -

×

Duran™ Tubes à essai en verre à rebord droit

1 × د.ت 0,000

Duran™ Tubes à essai en verre à rebord droit

1 × د.ت 0,000 -

×

RACCORD DROIT APPLIQUES 83003/04

2 × د.ت 0,000

RACCORD DROIT APPLIQUES 83003/04

2 × د.ت 0,000 -

×

Four de pesée, série L 1200

1 × د.ت 0,000

Four de pesée, série L 1200

1 × د.ت 0,000 -

×

Oeil

1 × د.ت 0,000

Oeil

1 × د.ت 0,000 -

×

Algomètre à pince instrumentée pour rongeurs - Sans fil

1 × د.ت 0,000

Algomètre à pince instrumentée pour rongeurs - Sans fil

1 × د.ت 0,000 -

×

Cassettes d'inclusion avec couvercle B/250, blanc

1 × د.ت 0,000

Cassettes d'inclusion avec couvercle B/250, blanc

1 × د.ت 0,000 -

×

SMALGO: Analgésimètre pour petits animaux - Sans fil

1 × د.ت 0,000

SMALGO: Analgésimètre pour petits animaux - Sans fil

1 × د.ت 0,000 -

×

Filaments de Von Frey

1 × د.ت 0,000

Filaments de Von Frey

1 × د.ت 0,000 -

×

Laparo Apex PRO Base

1 × د.ت 0,000

Laparo Apex PRO Base

1 × د.ت 0,000 -

×

Tamiseuse AS 200 basic

1 × د.ت 0,000

Tamiseuse AS 200 basic

1 × د.ت 0,000 -

×

Extrudeuse double vis TSE 24 MC

2 × د.ت 0,000

Extrudeuse double vis TSE 24 MC

2 × د.ت 0,000 -

×

Photomètre 5-en-1 MD 100 : Chlore, pH, acide cyanurique, alcalinité-M, dureté du calcium

1 × د.ت 0,000

Photomètre 5-en-1 MD 100 : Chlore, pH, acide cyanurique, alcalinité-M, dureté du calcium

1 × د.ت 0,000 -

×

Velp Scientifica™ Agitateur vertical numérique HDL

2 × د.ت 0,000

Velp Scientifica™ Agitateur vertical numérique HDL

2 × د.ت 0,000 -

×

Armoires de sécurité S-LINE

1 × د.ت 0,000

Armoires de sécurité S-LINE

1 × د.ت 0,000 -

×

ZEISS™ - Microscope Axioscope 5/7 MAT

1 × د.ت 0,000

ZEISS™ - Microscope Axioscope 5/7 MAT

1 × د.ت 0,000 -

×

Système de respiration du sol SRS1000T

1 × د.ت 0,000

Système de respiration du sol SRS1000T

1 × د.ت 0,000 -

×

Titrateur automatique TitroLine™ 5000

1 × د.ت 0,000

Titrateur automatique TitroLine™ 5000

1 × د.ت 0,000 -

×

ZEISS™ –MEB Sigma GeminiSEM

1 × د.ت 0,000

ZEISS™ –MEB Sigma GeminiSEM

1 × د.ت 0,000 -

×

Chambre de test CTC

1 × د.ت 0,000

Chambre de test CTC

1 × د.ت 0,000 -

×

Gilson™ Pointes de filtre PIPETMAN™ Tipack™

1 × د.ت 0,000

Gilson™ Pointes de filtre PIPETMAN™ Tipack™

1 × د.ت 0,000 -

×

ZEISS™ – Visioner 1

1 × د.ت 0,000

ZEISS™ – Visioner 1

1 × د.ت 0,000 -

×

Asclepius TBK 65 4K Table de dissection virtuelle

1 × د.ت 0,000

Asclepius TBK 65 4K Table de dissection virtuelle

1 × د.ت 0,000 -

×

Arène Open Field

1 × د.ت 0,000

Arène Open Field

1 × د.ت 0,000 -

×

Simulation d’écran de défibrillateur DAE Mindray BeneHeart C2® pour système REALITi 360

1 × د.ت 0,000

Simulation d’écran de défibrillateur DAE Mindray BeneHeart C2® pour système REALITi 360

1 × د.ت 0,000 -

×

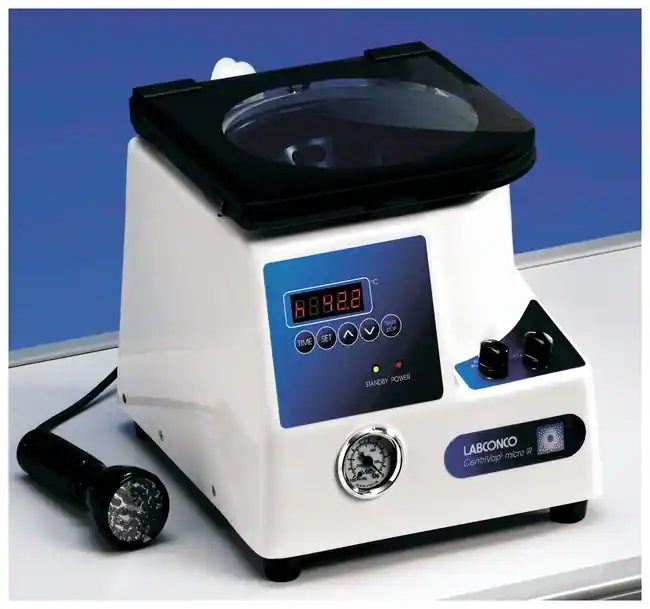

Concentrateur sous vide micro IR CentriVap™

1 × د.ت 0,000

Concentrateur sous vide micro IR CentriVap™

1 × د.ت 0,000 -

×

Labyrinthe en croix surélevé : EPM3C - seulement 3 clicks !

1 × د.ت 0,000

Labyrinthe en croix surélevé : EPM3C - seulement 3 clicks !

1 × د.ت 0,000 -

×

Test de gradient thermique 2.0

1 × د.ت 0,000

Test de gradient thermique 2.0

1 × د.ت 0,000 -

×

Memmert™ Enceinte Hygrométrique HCP50

1 × د.ت 0,000

Memmert™ Enceinte Hygrométrique HCP50

1 × د.ت 0,000 -

×

DURAN™ Bocal, avec couvercle à bouton, à bord poli

1 × د.ت 0,000

DURAN™ Bocal, avec couvercle à bouton, à bord poli

1 × د.ت 0,000

Sous-total : د.ت 0,000