-

×

X10 SEPARATEUR 8X8 BOITE 133 25 MM

1 × د.ت 0,000

X10 SEPARATEUR 8X8 BOITE 133 25 MM

1 × د.ت 0,000 -

×

ADAPTATEUR DE PIPETTE EN SILICONE

1 × د.ت 0,000

ADAPTATEUR DE PIPETTE EN SILICONE

1 × د.ت 0,000 -

×

Mesh basket, Mask 8x8x1 mm, (WxDxH) 120x120x120mm

1 × د.ت 0,000

Mesh basket, Mask 8x8x1 mm, (WxDxH) 120x120x120mm

1 × د.ت 0,000 -

×

x500 Transfer Pipette ST 3mL, pack of 20

1 × د.ت 0,000

x500 Transfer Pipette ST 3mL, pack of 20

1 × د.ت 0,000 -

×

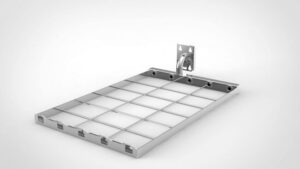

Lower level basic shelf

1 × د.ت 0,000

Lower level basic shelf

1 × د.ت 0,000 -

×

Pipeteur Manuel Fisherbrand 0,1-100ml

2 × د.ت 0,000

Pipeteur Manuel Fisherbrand 0,1-100ml

2 × د.ت 0,000 -

×

X25 insenreinigungspapier, 100 x 150mm, Heftchen F

1 × د.ت 0,000

X25 insenreinigungspapier, 100 x 150mm, Heftchen F

1 × د.ت 0,000 -

×

Micropipette Fisherbrand Elite 12 canaux 12x5-50µL

1 × د.ت 0,000

Micropipette Fisherbrand Elite 12 canaux 12x5-50µL

1 × د.ت 0,000 -

×

Vacuum system Fisherbrand

1 × د.ت 0,000

Vacuum system Fisherbrand

1 × د.ت 0,000 -

×

Micropipette Fisherbrand Elite 8 canaux 8x10-100µL

1 × د.ت 0,000

Micropipette Fisherbrand Elite 8 canaux 8x10-100µL

1 × د.ت 0,000 -

×

x500 Transfer Pipette graduated NST 1mL

1 × د.ت 0,000

x500 Transfer Pipette graduated NST 1mL

1 × د.ت 0,000 -

×

X500 PIPETTE 2ML ST PAPIER/PLAST

1 × د.ت 0,000

X500 PIPETTE 2ML ST PAPIER/PLAST

1 × د.ت 0,000 -

×

X200 PIPETTE 25ML ST VRAC

1 × د.ت 0,000

X200 PIPETTE 25ML ST VRAC

1 × د.ت 0,000 -

×

X288 Fisherbrand 60ml WM clear graduated glass typ

1 × د.ت 0,000

X288 Fisherbrand 60ml WM clear graduated glass typ

1 × د.ت 0,000 -

×

Micropipette Fisherbrand Elite 0,2-2µL .

1 × د.ت 0,000

Micropipette Fisherbrand Elite 0,2-2µL .

1 × د.ت 0,000 -

×

X100 PAPIER CCM 501 200X200MM

2 × د.ت 0,000

X100 PAPIER CCM 501 200X200MM

2 × د.ت 0,000 -

×

Micropipette Fisherbrand Elite 8 canaux 8x30-300µL

2 × د.ت 0,000

Micropipette Fisherbrand Elite 8 canaux 8x30-300µL

2 × د.ت 0,000 -

×

PORTOIR RANGEMENT PIPETTES ACRYLIC

2 × د.ت 0,000

PORTOIR RANGEMENT PIPETTES ACRYLIC

2 × د.ت 0,000 -

×

PALE CENTRIFUGE 70 MM L650 MM

1 × د.ت 0,000

PALE CENTRIFUGE 70 MM L650 MM

1 × د.ت 0,000 -

×

VORTEX MIXER, FIXED 2800RPM, 4.5MM ORBIT

1 × د.ت 0,000

VORTEX MIXER, FIXED 2800RPM, 4.5MM ORBIT

1 × د.ت 0,000 -

×

X100 BECHER PS 1000ML

2 × د.ت 0,000

X100 BECHER PS 1000ML

2 × د.ت 0,000 -

×

X1000 Pointe Fisherbrand SureOne Nano 0,1-5µl, cri

1 × د.ت 0,000

X1000 Pointe Fisherbrand SureOne Nano 0,1-5µl, cri

1 × د.ت 0,000 -

×

POIRE D'ASPIRATION 30ML

1 × د.ت 0,000

POIRE D'ASPIRATION 30ML

1 × د.ت 0,000 -

×

X1000 CAP VIS 13MM FERME CAOUT/TEF

1 × د.ت 0,000

X1000 CAP VIS 13MM FERME CAOUT/TEF

1 × د.ت 0,000 -

×

X100 PIPETTE 50ML NOSTRIPE ST VRAC

1 × د.ت 0,000

X100 PIPETTE 50ML NOSTRIPE ST VRAC

1 × د.ت 0,000 -

×

X500 PIPETTE 5ML NO STRIPE ST VRAC

1 × د.ت 0,000

X500 PIPETTE 5ML NO STRIPE ST VRAC

1 × د.ت 0,000 -

×

Table top stand for handvac and accessories

1 × د.ت 0,000

Table top stand for handvac and accessories

1 × د.ت 0,000 -

×

TRAY BIOHAZARD EASY CLEAN 113 X 54CM

1 × د.ت 0,000

TRAY BIOHAZARD EASY CLEAN 113 X 54CM

1 × د.ت 0,000 -

×

X1000 CAP ALU 8MM UC SIL/PTFE

1 × د.ت 0,000

X1000 CAP ALU 8MM UC SIL/PTFE

1 × د.ت 0,000 -

×

Dessicateur complet 100 MM avec couvercle à bouton

1 × د.ت 0,000

Dessicateur complet 100 MM avec couvercle à bouton

1 × د.ت 0,000 -

×

ZEISS™ –Microscope Smartzoom 5

1 × د.ت 0,000

ZEISS™ –Microscope Smartzoom 5

1 × د.ت 0,000 -

×

X100 BECHER TRICORNE PP 250ML GRAD

1 × د.ت 0,000

X100 BECHER TRICORNE PP 250ML GRAD

1 × د.ت 0,000 -

×

X100 PIPETTE 50ML ST VRAC

1 × د.ت 0,000

X100 PIPETTE 50ML ST VRAC

1 × د.ت 0,000 -

×

Single channel plastic adapter for disposal tip

1 × د.ت 0,000

Single channel plastic adapter for disposal tip

1 × د.ت 0,000 -

×

X1000 BOUCHON A VIS 9MM

1 × د.ت 0,000

X1000 BOUCHON A VIS 9MM

1 × د.ت 0,000 -

×

X10 Adaptateur pour Pointe de Distribution Fisherb

1 × د.ت 0,000

X10 Adaptateur pour Pointe de Distribution Fisherb

1 × د.ت 0,000 -

×

Module for 5 distributors,2 possible per level

1 × د.ت 0,000

Module for 5 distributors,2 possible per level

1 × د.ت 0,000 -

×

X960 Pointe Fisherbrand SureOne 5-300µl, cristal,

1 × د.ت 0,000

X960 Pointe Fisherbrand SureOne 5-300µl, cristal,

1 × د.ت 0,000 -

×

Stirrer shaft PTFE 12x750EX mm

1 × د.ت 0,000

Stirrer shaft PTFE 12x750EX mm

1 × د.ت 0,000 -

×

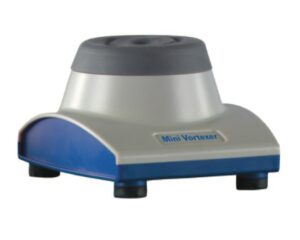

Mini Vortex Mixer Grey/Blue

1 × د.ت 0,000

Mini Vortex Mixer Grey/Blue

1 × د.ت 0,000 -

×

MAGNETOMRÖRARE MINI DNA FB70805

1 × د.ت 0,000

MAGNETOMRÖRARE MINI DNA FB70805

1 × د.ت 0,000 -

×

LARGE AMPOULE TUBE HOLDER

1 × د.ت 0,000

LARGE AMPOULE TUBE HOLDER

1 × د.ت 0,000 -

×

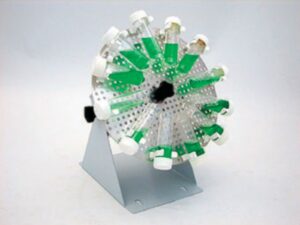

3 TIER DISC ASSEMBLY COMPLETE WITH 12 CLIPS FOR

2 × د.ت 0,000

3 TIER DISC ASSEMBLY COMPLETE WITH 12 CLIPS FOR

2 × د.ت 0,000 -

×

Support for Erlenmeyer flasks

2 × د.ت 0,000

Support for Erlenmeyer flasks

2 × د.ت 0,000 -

×

Gel de silice colloidale

1 × د.ت 0,000

Gel de silice colloidale

1 × د.ت 0,000 -

×

X1000 CAP PP BLUE SEPTUM PTFE/SIL 9MM

1 × د.ت 0,000

X1000 CAP PP BLUE SEPTUM PTFE/SIL 9MM

1 × د.ت 0,000 -

×

CENTRIFUGRÖR PP SNÄPPLOCK 1,5ML BLÅ FP=1000

1 × د.ت 0,000

CENTRIFUGRÖR PP SNÄPPLOCK 1,5ML BLÅ FP=1000

1 × د.ت 0,000 -

×

Mesh basket, Mask 8x8x1 mm, (WxDxH) 130x130x130mm

1 × د.ت 0,000

Mesh basket, Mask 8x8x1 mm, (WxDxH) 130x130x130mm

1 × د.ت 0,000 -

×

X1000 Pointe Fisherbrand SureOne 5-300µl, cristal,

1 × د.ت 0,000

X1000 Pointe Fisherbrand SureOne 5-300µl, cristal,

1 × د.ت 0,000 -

×

X1000 SEPT MOULE 20MM BUTYL/PTFE

1 × د.ت 0,000

X1000 SEPT MOULE 20MM BUTYL/PTFE

1 × د.ت 0,000 -

×

Swivel clamp 12.7mm to 19mm dia Fisherbrand

1 × د.ت 0,000

Swivel clamp 12.7mm to 19mm dia Fisherbrand

1 × د.ت 0,000 -

×

Bain-marie numérique

1 × د.ت 0,000

Bain-marie numérique

1 × د.ت 0,000 -

×

SINGLE TUBE HOLDER

1 × د.ت 0,000

SINGLE TUBE HOLDER

1 × د.ت 0,000 -

×

X100 FILTRE HPLC NYLON 0,45µ

1 × د.ت 0,000

X100 FILTRE HPLC NYLON 0,45µ

1 × د.ت 0,000 -

×

Mesh basket, Mask 8x8x1 mm, (WxDxH) 130x130x130mm

1 × د.ت 0,000

Mesh basket, Mask 8x8x1 mm, (WxDxH) 130x130x130mm

1 × د.ت 0,000 -

×

X12 Fisherbrand LDPE Dispensing Bottle 125ml, clos

2 × د.ت 0,000

X12 Fisherbrand LDPE Dispensing Bottle 125ml, clos

2 × د.ت 0,000 -

×

BECHER 600ML DIA:95MM

1 × د.ت 0,000

BECHER 600ML DIA:95MM

1 × د.ت 0,000 -

×

X12 Fisherbrand LDPE Dispensing Bottle 250ml, clos

1 × د.ت 0,000

X12 Fisherbrand LDPE Dispensing Bottle 250ml, clos

1 × د.ت 0,000 -

×

poids feuille 200mg E2 inox

1 × د.ت 0,000

poids feuille 200mg E2 inox

1 × د.ت 0,000 -

×

Base de dessicateur 100 MM ISO13130/DIN12491

1 × د.ت 0,000

Base de dessicateur 100 MM ISO13130/DIN12491

1 × د.ت 0,000 -

×

Capuchon de Kapsenberg, en aluminium

1 × د.ت 0,000

Capuchon de Kapsenberg, en aluminium

1 × د.ت 0,000 -

×

X5 Fisherbrand PTFE Turbo Stirrer Bar, Octahedral

1 × د.ت 0,000

X5 Fisherbrand PTFE Turbo Stirrer Bar, Octahedral

1 × د.ت 0,000

Sous-total : د.ت 0,000