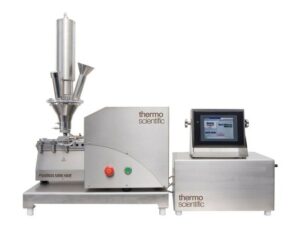

The Pharma mini Implant Line offers a complete solution for developing and producing injectable drug delivery systems. High-quality components and precise automation with integrated Quality Control and documentation assures consistent drug implant manufacturing.

Pharma mini Implant Line advantages

Hermetically sealed material container for maximum operator and product safety

High accuracy gravimetric feeding (± 0.5%, depending on material)

Reproducible and stable extrusion process up to 100 g/h

Accurate diameter control adjustable in the range of 0.5mm and 2.0mm; precision of final product is ± 0.005% to 0.05% (depending on physical parameters of the compound used)

Exact cutting of implant strand into specified length

Automated sorting of in-spec and out-of-spec product for 100% quality assurance

Integrated software control system for process monitoring, documentation and displaying all relevant system and process data

21 CFR part 11 compliant Batch Report and Audit Trail

Pharma mini Implant Line components

Container with containment valve

Gravimetric feeder with feeder screws and feeder stand

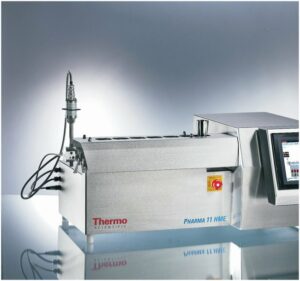

Pharma mini HME micro compounder with co- or counter-rotating screws

Filament diameter control and cutting unit with sorting unit

PLC with integration of all Pharma mini implant line instruments

Chiller unit

Avis

Il n’y a pas encore d’avis.