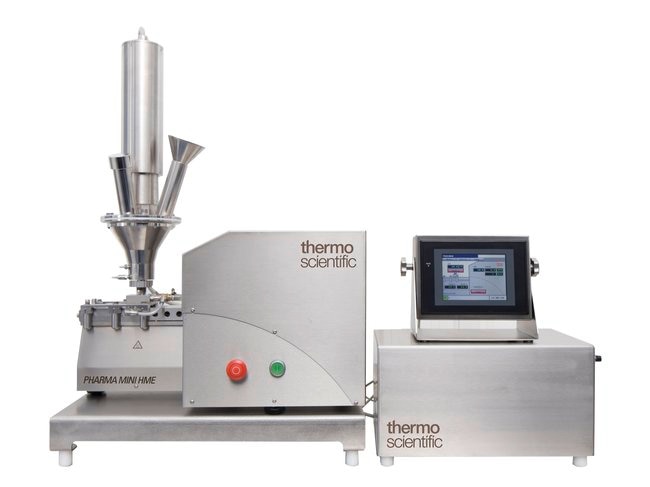

With the Pharma mini HME, we offer a micro twin-screw compounder which requires as little as three grams of total material to identify the right drug candidates for hot melt extrusion. The compounder with conical co- or counter-rotating screws is designed to minimize waste and reduce downtime necessary for cleaning.

Requires only 3g (4mL) of material for compounding

Small footprint, fanless design with separate, touch-screen control for operation in fume cabinet or glovebox applications

Removable and exchangeable product contact parts for quick and easy cleaning

IP 54 for protection against dust and water allows the Pharma mini HME to be spray-washed

Useable as small-scale production unit for throughputs of 100g/h

Touch screen control with user levels and password protection

Data logging software as option to record temperatures, torque, and screw speed

Optional batch conversion kit to use the Pharma mini HME as small batch mixer

Complementary workflow solution when coupled with the Thermo Scientific™ HAAKE™ MiniJet injection molder

Recommended for:

Materials:

Pharmaceutical ingredients (API’s)

Excipients

Medical polymers

Drug delivery systems

Soft gels

Applications:

Hot melt extrusion

Medical devices

Implants

Controlled drug release

Handling and processing of highly potent API’s in a glovebox

A small footprint reduces clean room volumes, and lower ingredient consumption reduces handling and operator exposure.

Reviews

There are no reviews yet.