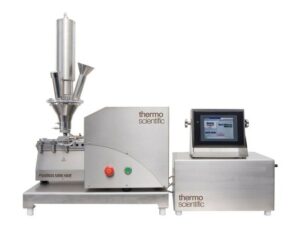

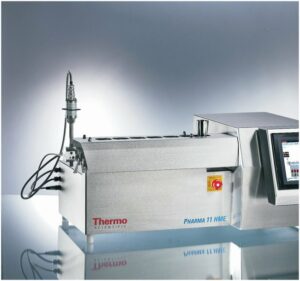

The Pharma 24 Twin-Screw Extruder features:

A small footprint to take up less space in clean rooms

Continuous operation which consumes fewer utilities than traditional batch processes

High free volume screw design

A small process inventory

Lower ingredient consumption which reduces handling and operator exposure

Segmented screws and barrel

Removable screws and liners

PAT Compatibility: PAT can be applied to your process to monitor parts of theprocess such as homogeneity of mixing or moisture content to assure required product quality. The Pharma 24 Extruder can be used with a range of PAT instruments such as Thermo Scientific™ FT-NIR system.

Options: We offer a full range of GMP compliant ancillaries which are matched to the extruder performance. This downstream equipment can be integrated into the extruder control system.

For TSG configurations: available ancillaries include volumetric or gravimetric dosing feeders and liquid injection pumps.

In addition, self-contained units of either configuration can be operated with recirculating chillers to reduce water consumption.

TSG configuration recommended for:

Wet granulation

Dry/melt granulation

For HME configurations: available ancillaries include volumetric or gravimetric dosing feeders, air cooled conveyors for product cooling, strand and face-cut pelletizers to make pellets, or chill roll/flaker units for rapid product cooling and flaking.

HME configuration recommended for:

Solubility enhancement

Modified release

Co-extrusion

Drug delivery systems

Biomedical products

Reviews

There are no reviews yet.